Les 8 idées fausses les plus répandues sur l’éclairage DEL: Part 2

Au cours des cinq dernières années, les DEL et les systèmes de commande ont été utilisés dans un vaste éventail d’applications résidentielles et commerciales. Toutefois, des idées fausses persistent au sujet des DEL. Il s’agit d’une technologie récente surtout si on la compare aux technologies d’éclairage qui l’ont précédée et l’auteur croit qu’il est temps de dissiper les mythes qui persistent et de parler de la performance, la valeur et les applications des DEL. Voici huit mythes discutés dans ce texte : Tous les DEL sont les mêmes, les DEL sont trop chers, les DEL sont tellement efficaces que les commandes sont inutiles, les DEL à gradation ne fonctionnent pas bien et réduisent la durée de vie des appareils d’éclairage, les fonctions de contrôle ne sont pas nécessaires, les prix vont baisser il est préférable d’attendre, les DEL ne sont pas efficaces dans des environnements à haute température, les DEL sont soit trop brillants ou pas assez. Nous continuons cette semaine l’exploration de ces mythes.

In the last five years, LEDs and controls have been widely used in a broad range of general lighting applications, from residential to commercial. However, there are a number of persistent misconceptions about LEDs that do not apply. Because LEDs are relatively new compared to legacy lighting types, it’s time to dispel the myths and set the record straight about their performance, value, and applicability. In this second of two parts, here are the final four of eight misconceptions. The first four appeared in our November 10 issue.

Myth 5: control capabilities (bells and whistles) are not necessary

Fact 5: an intelligent LED lighting system with integrated controls provides value beyond cost-effective light.

Control capabilities are not optional when efficiency is the goal. In addition to energy efficiency savings, intelligent LED lighting systems with granular controls provide:

• unprecedented visibility into energy and other valuable operational data. For example, facility staff can view occupancy patterns over a given period of time to see where activity is concentrated and correlate that information with other enterprise data to optimize merchandise placement in retail and distribution environments.

• the ability to monitor energy loads from non-lighting systems and circuits, and share these data — with permission-based access — with other users across the enterprise.

• an API to exchange data between the lighting software platform and third-party systems, simplifying corporate sustainability reporting, for example.

Myth 6: LED prices will go down, so it pays to wait

Fact 6: waiting for LED fixture prices to drop will cost you money.

The major LED chip price drops have already happened; the rest will be incremental. However, the energy savings from upgrading to LEDs far exceed any modest price declines in LED-based fixtures. So waiting for a price drop will cost more in energy savings than savings from LED price declines. Here’s why: a quick glimpse at a typical facility’s operating budget shows that lighting is one of the largest non-process energy loads.

The major factors associated with industrial lighting are up-front costs and energy use. By reducing energy usage 50% to 90%, LEDs pay back in energy savings much more than could ever be accrued through incremental LED price declines. If anything, energy’s upward price trend makes waiting even more costly.

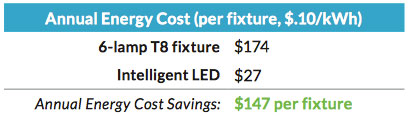

The math: using the same $0.10/kWh rate, for example, a single 6-lamp T8 fixture typically consumes $174 in lighting-related energy costs per year. An intelligent LED fixture consumes just $27, resulting in a net savings of $147 per year (not including the additional daylight harvesting, maintenance, and/or refrigeration savings associated with intelligent LEDs).

Myth 7: LEDs don’t work well in high-temperature environments

Fact 7: well-designed LEDs work well in a broad range of environments.

During temperature tests conducted by independent labs, LEDs performed equally as well as fluorescents and HID fixtures (see note below on testing parameters). Quality matters, and a well-designed lighting system that carefully manages heat dissipation is a prerequisite for lighting operating at any temperature — hot, cold, or anywhere in between.

At the same time, it is important to note that LEDs perform extraordinarily well in cold environments, an area that has been particularly challenging for other types of lighting, such as fluorescent and HID.

Note: an important indicator of the quality of an LED solution’s thermal management is junction temperature, which measures the internal temperature of the LED chip within the fixture for specified operating intervals — usually 6,000, 10,000, or even 18,000 hours. These values are commonly available as part of industry standard tests performed by independent testing labs.

Best advice:be sure to request all testing data from LED fixture vendors, including LM-80 (LED chip) and TM-21 (LED chip within specific fixtures).

Myth 8: LEDs are too bright, or not bright enough

Fact 8: well-designed LED fixtures provide the right light output to manage glare and light placement while eliminating the yellowish colours of high-pressure sodium and HID lights.

LED fixtures vary dramatically by fixture, with different options for lumen output, optics, directionality, and colour temperature. Fixture layout and mounting height also play key roles in successful lighting plans.

Important to note:

• high lumen output does not necessarily correlate to adequate light levels at the target surface(s). In fact, many fixtures that advertise high lumen output do not manage light effectively. These fixtures are sometimes labelled “glare bombs,” and are often sub-par performers, even if premium priced.

• well-designed optics are used to direct the lumen output from LED chips to the target surface. Look for fixtures with optics options to match your environment’s needs. Narrow, wide, aisle, or diffuse lenses should all be available.

• directionality is important. Look for fixtures with flexible light bars that can deliver light in the direction needed, including to the ceiling if necessary.

• colour temperature choices are important, and vary from environment to environment. Higher colour temperature — typically 5,000 K — is used in warehousing or manufacturing, while 4,000 K is used in convention centres or retail environments.

• high-quality fixtures with options for lumen output and optics packages can provide flexibility to reduce fixture count in certain applications. Variables include mounting height, foot-candle requirements, and space layout. With the ability to position light bars for optimal light distribution, sometimes a smaller number of higher output fixtures can be the better solution.

• work with a qualified and proven lighting partner who will present the best and most economical lighting design that meets the facility’s needs.

Closing thoughts

Interest in LED lighting is at an all-time high as energy efficiency and corporate sustainability initiatives are increasingly important worldwide. But because LEDs are fundamentally different from other lighting types, it is critical to understand the characteristics, benefits, and opportunities they present.

Read the first four misconceptions in our November 10 issue.

This article was first published online as a Digital Lumens white paper: http://digitallumens.com/resources/white-papers/.